Sorting

With our next-generation solutions for recycling, Envac leads the way in shaping a more sustainable future and the circular economy. Our sorting solutions can be used by cities of all sizes and reduce transport and collection costs by at least 50% compared to competing systems.

Multiple recyclables and collection methods – one sorting plant

Our next-generation sorting system can be used together with the Envac pneumatic waste collection system, but can also be added to modernise old, traditional methods of waste collection. In both cases, Envac’s market-leading sorting solution is cost-efficient and straight-forward while increasing recycling.

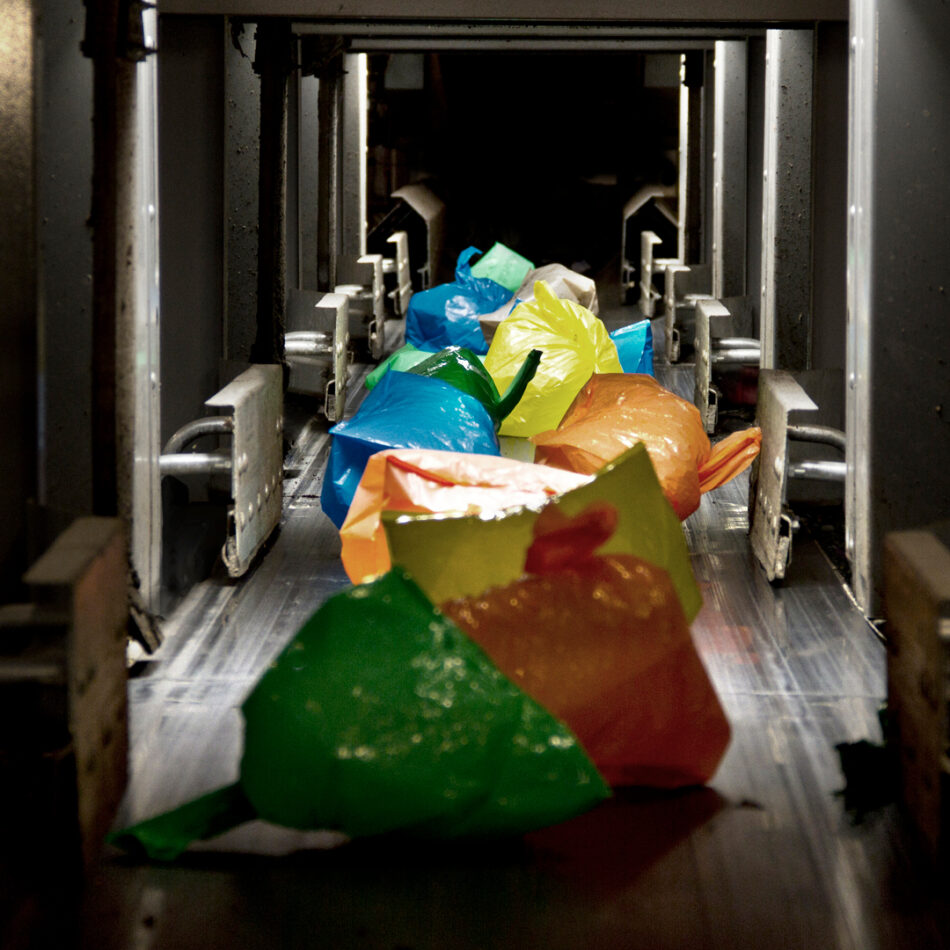

The system is based on colour coding with each recyclable having its specific coloured bag that the users sort their recyclables in. This makes it easy for users, even if they are recycling novices. The bags can all be disposed of in the same waste bin or waste inlet to be transported to the sorting plant where the bags are sorted based on their colour and put in their corresponding container. Streamlining transportation means that our sorting system reduces costs and emissions from transport.

Separating at home

As in any waste management system, the separation of waste from recyclable materials is done at home by residents and users. Getting users engaged in separating and recycling can be a challenge, especially when it is introduced for the first time. To drive engagement, clear information and making separating and disposal easy are key factors for success.

We have decades of experience in this field, and our local offices are usually involved in customizing the information campaign together with the system owner. We have had great success implementing our system. For example, in the GrowSmarter project at Valla torg, Sweden, households reduced their general waste by 65 per cent when our system replaced old recycling methods.

Optical sorting and AI – sustainably smart

The colour codes used in our system enable crucial business data collection and analysis using AI. The colour code is used for the optical sorting at the collection station.

We collect information on things such as volume per fraction or recyclable; how well the sorting has been done by the users; how and when volumes of certain recyclables are disposed of; and much more. We use all this data to further optimize our system beyond any conventional system.

We use AI to configure the system’s capacity and collection intervals, as well as to understand user behaviour to incentivize further recycling. This makes our system sustainably smart and a crucial part of moving towards a circular economy.

Flexible system for cities of all sizes

The sorting system handle recyclables such as food waste, paper packaging, plastic packaging, metal, textile, newspapers, colourless glass, coloured glass and combustible waste.

With such flexibility we are confident we can provide a system that fits every need and any size of city or municipality.

Projects

Recycling lies at the heart of a circular economy, but old and traditional methods are both challenging and costly. In contrast, our optical sorting solutions can be used by cities of all sizes and reduces transport and collection costs by at least 50% compared to competing systems.